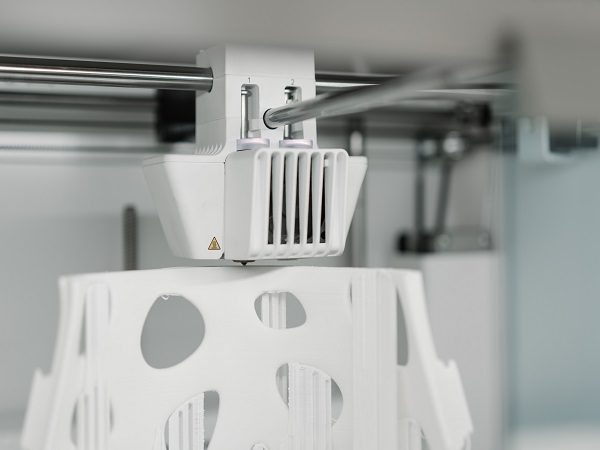

3D Printing in Plumbing: Custom Solutions for Modern Challenges

Introduction:

In the ever-evolving landscape of plumbing, innovation plays a pivotal role in addressing modern challenges. One such groundbreaking technology that has made waves in the plumbing industry is 3D printing. This cutting-edge technology has redefined how plumbers approach problem-solving, providing custom solutions that are both efficient and cost-effective.

The Evolution of Plumbing with 3D Printing:

Traditionally, plumbing solutions have been crafted using conventional methods that often pose limitations in terms of customization and precision. However, with the advent of 3D printing, the game has changed. Plumbers now have the ability to create bespoke components tailored to the unique requirements of each project.

Customization for Enhanced Efficiency:

The beauty of 3D printing lies in its ability to deliver highly customized solutions. Plumbers can now design and manufacture intricate parts that seamlessly integrate with existing plumbing systems. This level of customization not only enhances the overall efficiency of the system but also minimizes the need for frequent repairs and replacements.

Cost-Effective Solutions:

In the world of plumbing, cost-effectiveness is a crucial factor. Traditional methods often involve mass production of standardized components, leading to excess material waste and increased costs. 3D printing, on the other hand, allows for on-demand manufacturing, reducing waste and ensuring that each component serves a specific purpose. This leads to significant cost savings, benefiting both plumbers and clients.

Rapid Prototyping for Precision:

The iterative nature of plumbing projects often requires multiple rounds of testing and adjustments. 3D printing facilitates rapid prototyping, allowing plumbers to quickly produce and test various designs before finalizing the ideal solution. This not only saves time but also ensures a higher level of precision in the final product.

Environmental Sustainability:

As the world becomes increasingly conscious of environmental impact, 3D printing in plumbing aligns with the principles of sustainability. By minimizing material waste and reducing the carbon footprint associated with traditional manufacturing processes, 3D printing emerges as an eco-friendly alternative in the plumbing industry.

Application of 3D Printing in Plumbing:

Custom Pipe Fittings:

3D printing enables the creation of unique pipe fittings tailored to the specific dimensions and angles required for a project. This ensures a seamless fit, reducing the risk of leaks and enhancing the overall durability of the plumbing system.

Prototyping Faucets and Fixtures:

Plumbers can use 3D printing to prototype faucets and fixtures, allowing them to test different designs and functionalities. This iterative process ensures that the final product meets both aesthetic and functional requirements.

Repairing Vintage Plumbing Systems:

For older buildings with vintage plumbing systems, finding replacement parts can be a challenge. 3D printing comes to the rescue by enabling the recreation of obsolete components, preserving the authenticity of the plumbing while ensuring its longevity.

Tailored Drainage Solutions:

3D printing allows plumbers to design custom drainage solutions that address specific challenges in a given space. Whether it’s optimizing water flow or preventing clogs, bespoke drainage components can be created to suit the unique requirements of each project.

Innovative Water Conservation Devices:

Plumbers can leverage 3D printing to develop innovative water conservation devices. This includes customized aerators, flow restrictors, and sensor-equipped fixtures that contribute to sustainable water usage.

Challenges and Future Prospects:

While 3D printing has undoubtedly revolutionized plumbing practices, it is not without its challenges. The initial investment in 3D printing technology and the learning curve associated with its implementation can be barriers for some plumbing professionals. However, as the technology continues to advance and become more accessible, these challenges are expected to diminish.

Looking ahead, the future of 3D printing in plumbing appears promising. As the technology becomes more widespread, we can anticipate further innovations, such as the use of advanced materials and enhanced printing techniques. This will open up new possibilities for creating even more durable, efficient, and sustainable plumbing solutions.

Conclusion:

3D printing has emerged as a game-changer in the field of plumbing, offering custom solutions to modern challenges. Its ability to provide tailored components, reduce costs, and contribute to environmental sustainability positions 3D printing as a valuable asset in the plumber’s toolkit. As the technology continues to evolve, we can expect an exciting future where 3D printing plays an increasingly integral role in shaping the landscape of plumbing innovation.